| |

Optional Equipment: Tooling for 1/2 in.

wall flared metal ends. Appropriate double dado, double internal or

punch type notchers can be mated with press and also a double end

squeezer and double end beveller with a core saw can also be mated

to with press to make a complete core cutting and capping machine.

Machine does 4 prick punches as standard but can be supplied with

six, eight or twelve prick punches

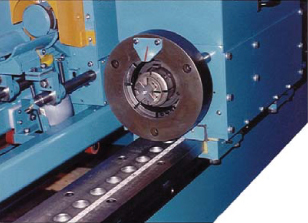

Operator sets length of core to be capped and then puts metal

end on each chuck, places notched core on saddles and lines up

notch with marker then touches Opti-Touch buttons and machine

will then press, prick punch, flare and crimp metal ends to

core, a pressure switch is then tripped returning all cylinders.

The capped core can be manually removed or automatically removed

from the machine.

|

|